Gear mold laser surface strengthening technology refers to the treatment of gear or mold surface with high energy density laser beam and coating or cladding material in the numerical control environment, changing the surface structure or composition to achieve surface phase transformation strengthening or reinforcement. Repaired technology.

Laser phase transformation enhanced metal materials The so-called laser phase transformation enhancement is to use a laser beam to scan the workpiece, so that the surface of the workpiece is rapidly heated to above the critical point of Ac3. When the thermal layer is removed, the temperature of the workpiece is caused by the heat conduction of the substrate. Entering the martensite or bainite region, martensite transformation or bainite transformation occurs, and the phase transformation strengthening process is completed.

The phase change strengthening process has the advantages of good surface quality, and the hardness and the depth of the strengthening layer can be controlled according to different materials, heat capacity of the workpiece, and laser processing parameters. The technical factors affecting the strengthening effect in the traditional heat treatment process have changed greatly in the role of laser phase transformation strengthening.

1. Dispersion strengthening and distortion Strengthening laser phase transformation strengthens austenite. When laser irradiation is stopped, martensite transformation occurs on the metal surface. Austenite formed in this process environment, whether it is the surface layer or the inner layer, has no chance of growing austenite grains. The diffused austenite grains form a diffuse martensite phase or bainite phase, which gives the structure a lattice strengthening and a dispersion strengthening effect. Moreover, the martensite lattice formed under chilling conditions has a higher defect density than conventional quenching. At the same time, the retained austenite also obtains a very high dislocation density, which makes the metal material have a distortion strengthening effect and the strength is greatly improved.

2. Non-oxidative decarburization and quenching In the traditional heat treatment, if there is no protective measure in the heating process, the oxidation and decarburization will occur, which will reduce the hardness, wear resistance, service performance and service life of the workpiece.

The light absorbing coating used in laser phase transformation enhancement has the property of protecting the surface of the workpiece from oxidation.

3. One of the reasons that the anti-fatigue mechanism of laser strengthening affects the fatigue resistance of metal materials is the initiation time of fatigue cracks. Wear and fatigue are promoted in the process of material damage. Wear groove marks can become the starting point of fatigue cracks, accelerate the initiation of fatigue cracks, and after the fatigue crack on the surface of the material, the surface roughness is seriously deteriorated and the wear will be intensified.

The laser strengthening layer has strong resistance to plastic deformation and anti-adhesive wear.

4. The cooling direction of the conventional heat treatment of the constant working layer is from the surface to the inside, the surface cooling rate is the fastest, and the cooling rate is gradually decreased from the surface and the inside, so the gradient distribution from the surface and the hardness value is obtained.

Although the heating direction of laser phase transformation strengthening is the same, the surface temperature is high, and the heating time is relatively long, up to 0.2-0.25 s, while the inner layer austenitizing is completed in the daytime, making the surface austenite It has a higher carbon concentration and a stronger solid solution strengthening effect. The direction of laser quenching and cooling is opposite to that of conventional heat treatment. It is from the inside and the inside. The inner layer temperature is low, but the cooling rate is the fastest. Although the outer layer temperature is high, it has the advantage of solid solution strengthening, but the cooling rate is the slowest, although the inner layer carbon The concentration is slightly lower, but the distortion enhancement and dispersion strengthening are more intense. This results in an almost constant distribution of hardness values ​​within the hardened layer.

The strong working layer such as laser reinforced parts avoids the phenomenon that the wear rate of the conventional heat-treated parts accelerates once the surface wears.

Gear laser phase change strengthening technology

1. Material problems Laser gears should be medium carbon steel, and low carbon steel should not be used.

If low carbon steel is used, the base of the gear will have no strength guarantee and reduce the bending fatigue strength.

2. The original state of the original state of the laser gear is the quenching and tempering state, the specific operation can be combined with the stress relief heat treatment after the gear blank forging. Forging billet normalizing and high temperature tempering to obtain the desired quenching and tempering state of the laser gear is a low-cost road.

3. Scanning mode The scanning mode of the laser gear mainly includes circumferential continuous scanning and axial splitting scanning.

4. Gear laser-enhanced pretreatment technology The proper pretreatment agent is one of the keys to ensure the laser laser strengthening treatment. It has always been a difficult problem in laser processing. Reasonable applicable pretreatment agent and treatment process can prevent the quenching crack on the gear surface, reduce the surface burning sensitivity, ensure the tooth surface precision after laser treatment, and increase the thickness of the hardened layer.

5. No lap joint technology and defocus difference problem Due to gear working conditions, the hard surface layer of the gear is required to be distributed along the tooth profile, and the shape of the gear is special. In addition, the round section of the gear joint cannot be overlapped by the quenching belt, so special broadband is required. Focus system.

In addition, since the irradiation of the tooth surface by the laser beam cannot ensure the same defocus amount in different parts of the tooth surface, the selection of the focus position is a key link to ensure the reasonable distribution of the tooth surface hardness.

6. Performance of laser gears The performance of laser gears is mainly three aspects: fatigue performance; if there are no broken teeth in laser gears and tempered gears, it proves that it has high bending fatigue resistance; wear resistance; performance .

Excellent deep discharge recoverability.

High energy density design, ideal for high current and high power discharge in UPS systems.

Slow self-discharge rate (<3% per month), ensuring constant power in standby or as part of a UPS system.

Heavy-duty, threaded copper alloy terminals for easy assembly, reduced maintenance, and enhanced safety.

High tin grid alloy minimizes gassing and delays corrosion, extending battery life with maintenance-free convenience.

Standby Use: UPS power supplies, emergency lighting, precision instrument backup, fire alarms, security systems, office automation, and more.

Solar Cell Power Generation: Street lighting, portable power supply, water pumping stations, rural power systems.

Combining market demands with personalized needs and progressive manufacturing techniques, OREMA is dedicated to providing the most cost-effective power solutions for industrial and commercial applications. Our mission is to empower global sustainable energy development with high-quality products, customized solutions, and attentive service, aiming to be the preferred supplier for our customers.

Combining market demands with personalized needs and progressive manufacturing techniques, OREMA is dedicated to providing the most cost-effective power solutions for industrial and commercial applications. Our mission is to empower global sustainable energy development with high-quality products, customized solutions, and attentive service, aiming to be the preferred supplier for our customers.

Laser phase transformation enhanced metal materials The so-called laser phase transformation enhancement is to use a laser beam to scan the workpiece, so that the surface of the workpiece is rapidly heated to above the critical point of Ac3. When the thermal layer is removed, the temperature of the workpiece is caused by the heat conduction of the substrate. Entering the martensite or bainite region, martensite transformation or bainite transformation occurs, and the phase transformation strengthening process is completed.

The phase change strengthening process has the advantages of good surface quality, and the hardness and the depth of the strengthening layer can be controlled according to different materials, heat capacity of the workpiece, and laser processing parameters. The technical factors affecting the strengthening effect in the traditional heat treatment process have changed greatly in the role of laser phase transformation strengthening.

1. Dispersion strengthening and distortion Strengthening laser phase transformation strengthens austenite. When laser irradiation is stopped, martensite transformation occurs on the metal surface. Austenite formed in this process environment, whether it is the surface layer or the inner layer, has no chance of growing austenite grains. The diffused austenite grains form a diffuse martensite phase or bainite phase, which gives the structure a lattice strengthening and a dispersion strengthening effect. Moreover, the martensite lattice formed under chilling conditions has a higher defect density than conventional quenching. At the same time, the retained austenite also obtains a very high dislocation density, which makes the metal material have a distortion strengthening effect and the strength is greatly improved.

2. Non-oxidative decarburization and quenching In the traditional heat treatment, if there is no protective measure in the heating process, the oxidation and decarburization will occur, which will reduce the hardness, wear resistance, service performance and service life of the workpiece.

The light absorbing coating used in laser phase transformation enhancement has the property of protecting the surface of the workpiece from oxidation.

3. One of the reasons that the anti-fatigue mechanism of laser strengthening affects the fatigue resistance of metal materials is the initiation time of fatigue cracks. Wear and fatigue are promoted in the process of material damage. Wear groove marks can become the starting point of fatigue cracks, accelerate the initiation of fatigue cracks, and after the fatigue crack on the surface of the material, the surface roughness is seriously deteriorated and the wear will be intensified.

The laser strengthening layer has strong resistance to plastic deformation and anti-adhesive wear.

4. The cooling direction of the conventional heat treatment of the constant working layer is from the surface to the inside, the surface cooling rate is the fastest, and the cooling rate is gradually decreased from the surface and the inside, so the gradient distribution from the surface and the hardness value is obtained.

Although the heating direction of laser phase transformation strengthening is the same, the surface temperature is high, and the heating time is relatively long, up to 0.2-0.25 s, while the inner layer austenitizing is completed in the daytime, making the surface austenite It has a higher carbon concentration and a stronger solid solution strengthening effect. The direction of laser quenching and cooling is opposite to that of conventional heat treatment. It is from the inside and the inside. The inner layer temperature is low, but the cooling rate is the fastest. Although the outer layer temperature is high, it has the advantage of solid solution strengthening, but the cooling rate is the slowest, although the inner layer carbon The concentration is slightly lower, but the distortion enhancement and dispersion strengthening are more intense. This results in an almost constant distribution of hardness values ​​within the hardened layer.

The strong working layer such as laser reinforced parts avoids the phenomenon that the wear rate of the conventional heat-treated parts accelerates once the surface wears.

Gear laser phase change strengthening technology

1. Material problems Laser gears should be medium carbon steel, and low carbon steel should not be used.

If low carbon steel is used, the base of the gear will have no strength guarantee and reduce the bending fatigue strength.

2. The original state of the original state of the laser gear is the quenching and tempering state, the specific operation can be combined with the stress relief heat treatment after the gear blank forging. Forging billet normalizing and high temperature tempering to obtain the desired quenching and tempering state of the laser gear is a low-cost road.

3. Scanning mode The scanning mode of the laser gear mainly includes circumferential continuous scanning and axial splitting scanning.

4. Gear laser-enhanced pretreatment technology The proper pretreatment agent is one of the keys to ensure the laser laser strengthening treatment. It has always been a difficult problem in laser processing. Reasonable applicable pretreatment agent and treatment process can prevent the quenching crack on the gear surface, reduce the surface burning sensitivity, ensure the tooth surface precision after laser treatment, and increase the thickness of the hardened layer.

5. No lap joint technology and defocus difference problem Due to gear working conditions, the hard surface layer of the gear is required to be distributed along the tooth profile, and the shape of the gear is special. In addition, the round section of the gear joint cannot be overlapped by the quenching belt, so special broadband is required. Focus system.

In addition, since the irradiation of the tooth surface by the laser beam cannot ensure the same defocus amount in different parts of the tooth surface, the selection of the focus position is a key link to ensure the reasonable distribution of the tooth surface hardness.

6. Performance of laser gears The performance of laser gears is mainly three aspects: fatigue performance; if there are no broken teeth in laser gears and tempered gears, it proves that it has high bending fatigue resistance; wear resistance; performance .

High Rate Battery Solutions by OREMA: Powering the Future

In today's rapidly evolving energy landscape, OREMA stands at the forefront, offering the pinnacle in high rate discharge battery technology. Our OREMA UNH series, a beacon of efficiency and reliability, is engineered for critical applications, ensuring uninterrupted power supply (UPS) systems and more.

High Rate Discharge Battery Excellence:

Our high rate discharge batteries, a core part of the OREMA UNH series, are designed for heavy-load discharge applications, promising a design life of 5-12 years in floating service. These batteries excel in delivering stable performance during high current discharges, thanks to robust grids and specially formulated active materials.Advanced AGM Technology:

At the heart of our innovation lies the advanced Absorbent Glass Mat (AGM) technology. This cutting-edge approach guarantees consistent backup power, vital for UPS systems and other critical applications. The UNH series showcases exceptional high-power discharge performance, offering abundant power in short periods, making them ideal for applications needing quick and reliable backup power sources.Reliability in Every Cell:

Renowned for their high reliability, our batteries withstand the rigors of continuous use, providing uninterrupted power when it matters most. This resilience makes them suitable for critical power applications where any downtime or power interruption could have severe consequences.Durability and Longevity:

Beyond reliable performance, these batteries boast impressive durability. Designed for extended life, they can endure repeated charging and discharging cycles without capacity loss. This ensures they consistently provide backup power over an extended period, offering peace of mind to our users.Features and Benefits of OREMA 12V High Rate Batteries:

High rate discharge construction for demanding applications.Excellent deep discharge recoverability.

High energy density design, ideal for high current and high power discharge in UPS systems.

Slow self-discharge rate (<3% per month), ensuring constant power in standby or as part of a UPS system.

Heavy-duty, threaded copper alloy terminals for easy assembly, reduced maintenance, and enhanced safety.

High tin grid alloy minimizes gassing and delays corrosion, extending battery life with maintenance-free convenience.

Diverse Applications of OREMA High Rate Battery Pack:

Our high rate batteries are versatile, catering to a wide range of applications:Standby Use: UPS power supplies, emergency lighting, precision instrument backup, fire alarms, security systems, office automation, and more.

Solar Cell Power Generation: Street lighting, portable power supply, water pumping stations, rural power systems.

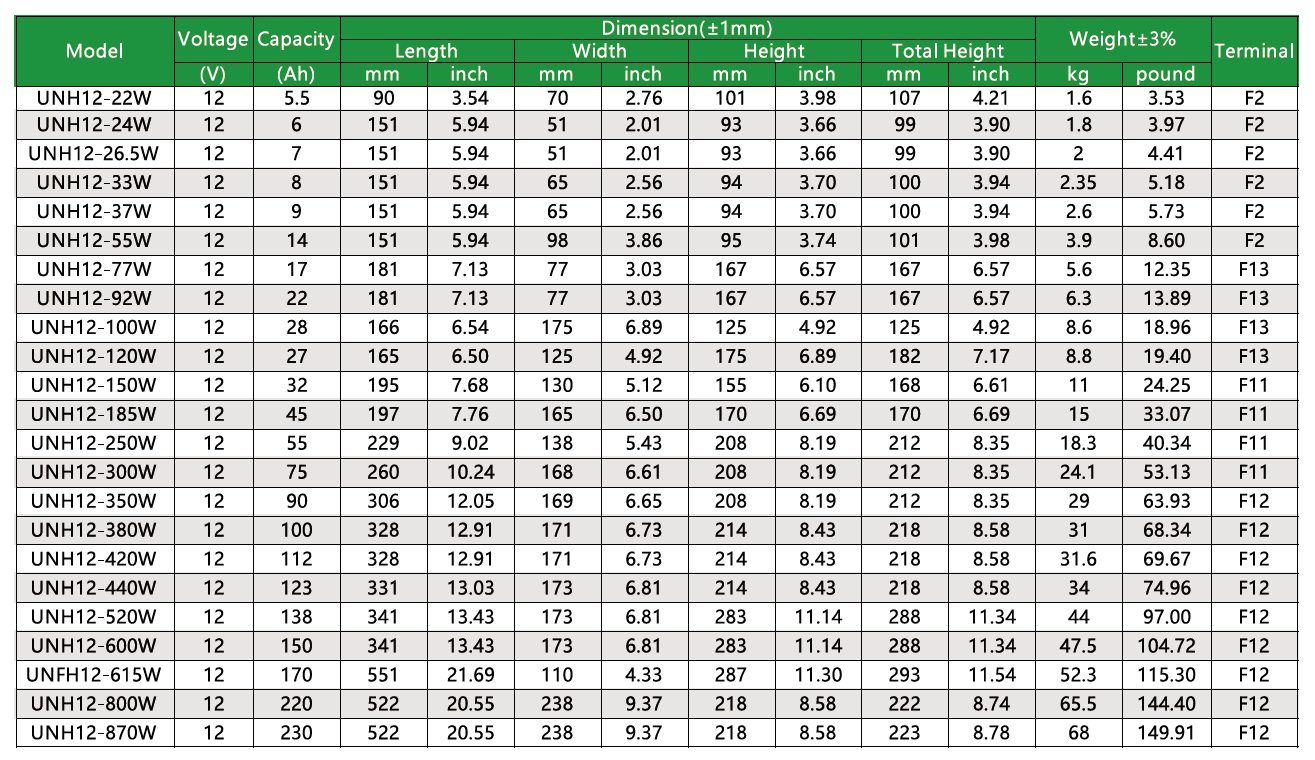

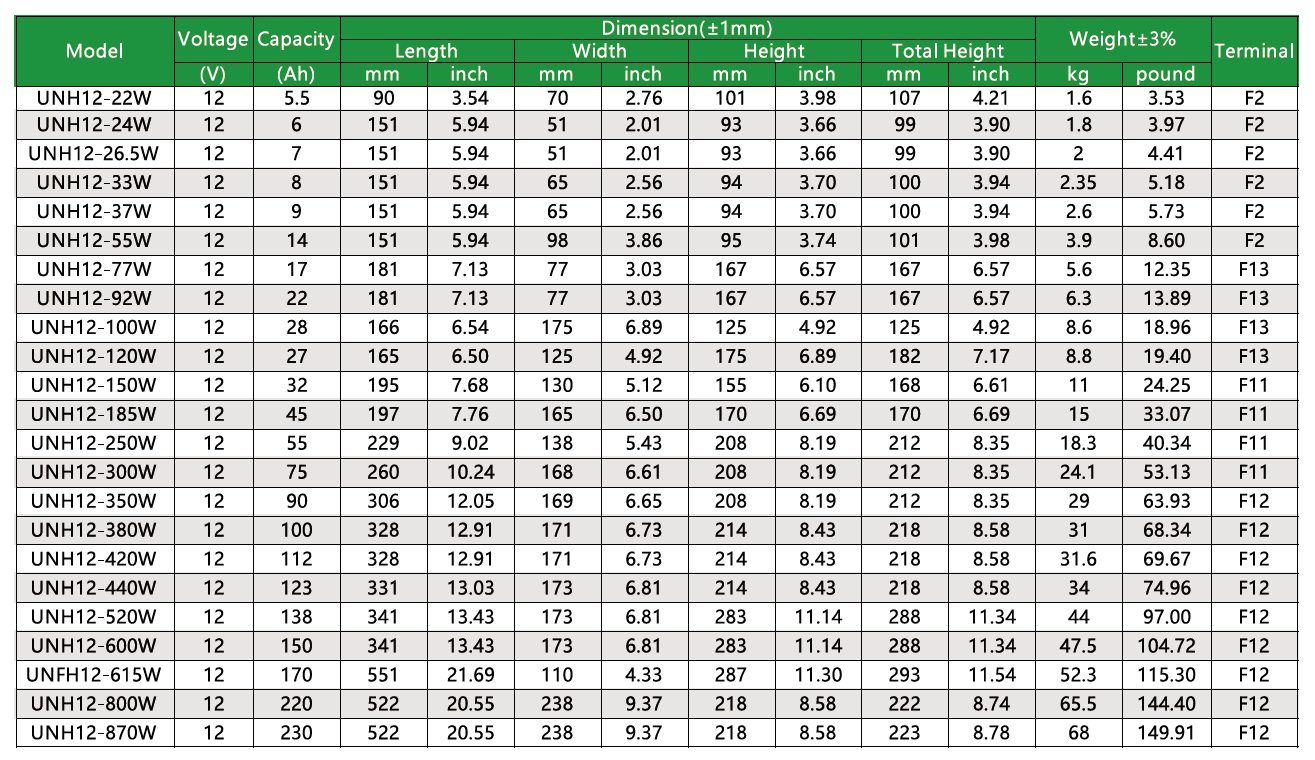

Specifications of OREMA UNH series high rate discharge batteries:

High Rate Battery,high rate discharge battery,High Rate Battery pack,high rate current battery,12V high rate batteries

OREMA POWER CO., LTD. , https://www.oremapower.com